Routing & BOM Routing Link

Routing Links are used to making an association between a routing and the BOM components that will be used in the process and the associated versions. ‘Routing Link Code’ links the Bill of Material to a Process Cycle and its Operation.

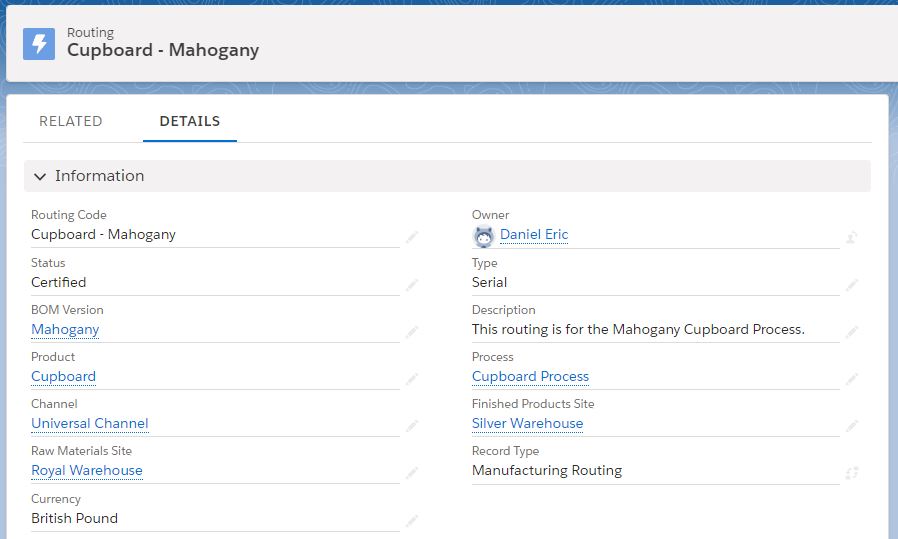

Routing

- Navigate to the app menu > Routing tab.

- Once in the Routing section, you can track the routing that is already created and also create a new routing.

- To create a new routing, click the “New” button.

- Select the Manufacturing Routing record type and click the “Next” button.

- Enter the Routing Code and select the Type and Status to be Certified.

- Select the Product, Channel, Raw Material and Finished Product sites.

- Enter the Maximum and Minimum lot size and click the “Save” button to create the Routing record.

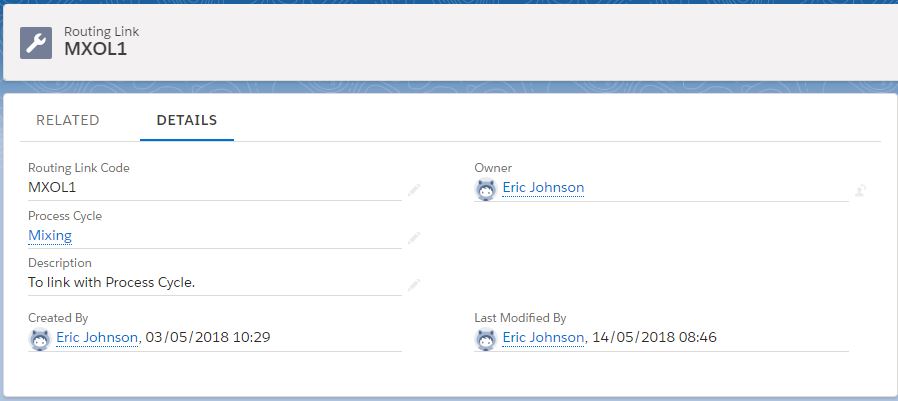

To add the Routing Link Code:

- Navigate to the Process > Process Cycle (Related List)

- In the Related list, scroll down to the Routing Links tab.

- Create new routing link by adding the routing link code, process cycle, and

- This Routing link code will be assigned to the Bill of Materials and the Operations.

Operations

- Navigate to the operations tab in the related list to Routings.

- Once in the Operations section, you can track the operations that are already recorded and create a new Operations record.

- Click the “New” button to create operations.

- Enter the Operation Code, the Operation No., and the Next Operation No.

- Select the Work Center, Quantity, and Fixed Cost details.

- Click the “Save” button to create the Operations record.