Stock Run Rate

Stock Run Rate gives an overview of the inventory, it shows how much stock you have at any given time. The stock run rate tracks the finished goods as well as the raw materials. It tracks stocks at all levels of the production process, from net inventory before the supply/produces, to supply/ produce and projected inventory to demand forecast/ actual demand. The complete insight of stock run rate is generated with the help of a master production schedule created for every finished and raw material product. The MPS essentially provides the planning function, extracting actual supply and demand data, and forecasts to deliver timely and accurate production plans. The forecast gives manufacturers the ability to anticipate product demand. The MPS also includes quantities or lot size of the items to be produced, production duration, and quantities available to promise. You can create the master production schedule by following the steps below.

- On the Product record, navigate to the related list and find Master Production Schedule.

- Once in the Master Production Schedule related list, you can track the master production schedules already filled in.

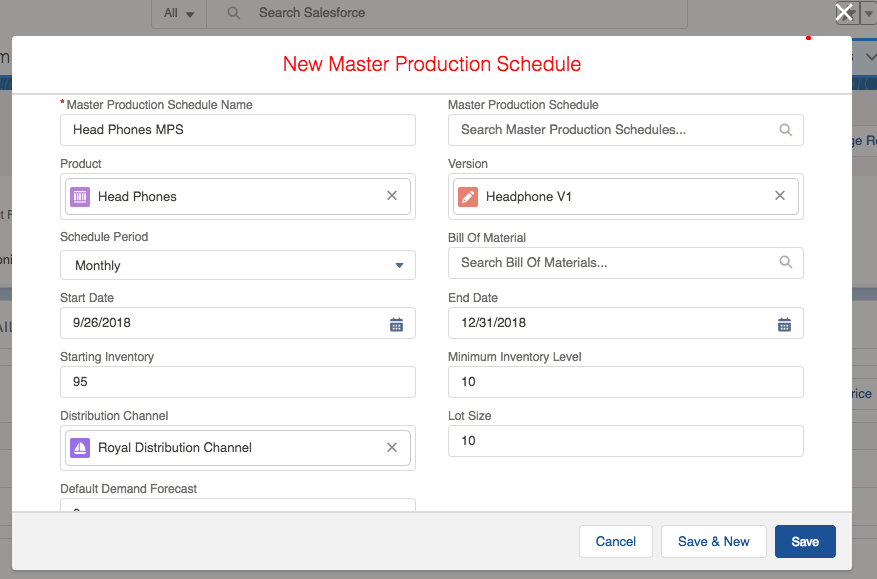

- To create a new Master Production Schedule, click the “New” button. You will be presented with a screen below.

- Enter the name of the Master Production Schedule and select the Product for which the MPS is created.

- Select the Version of the product and select the schedule period whether the production is scheduled weekly, monthly and yearly.

- Enter the Start and End dates of the master production schedule.

- Enter the Starting and Minimum Inventory Levels.

- Select the Distribution Channel and enter the Lot Size of the production and enter the Default Demand Forecast.

- Save the record to create a Master Production Schedule for a product.

- Once the Master Production Schedule is created, you need to create an MPS line item. Based on the start and end dates of the master production schedule MPS line items are created.

- Navigate to the related list of the master production schedule and find MPS Line Items.

- Click the “Generate MPS” button located on the top right corner of the master production schedule record.

- This creates the MPS Line Item records based on the start and end dates in the master production schedule.

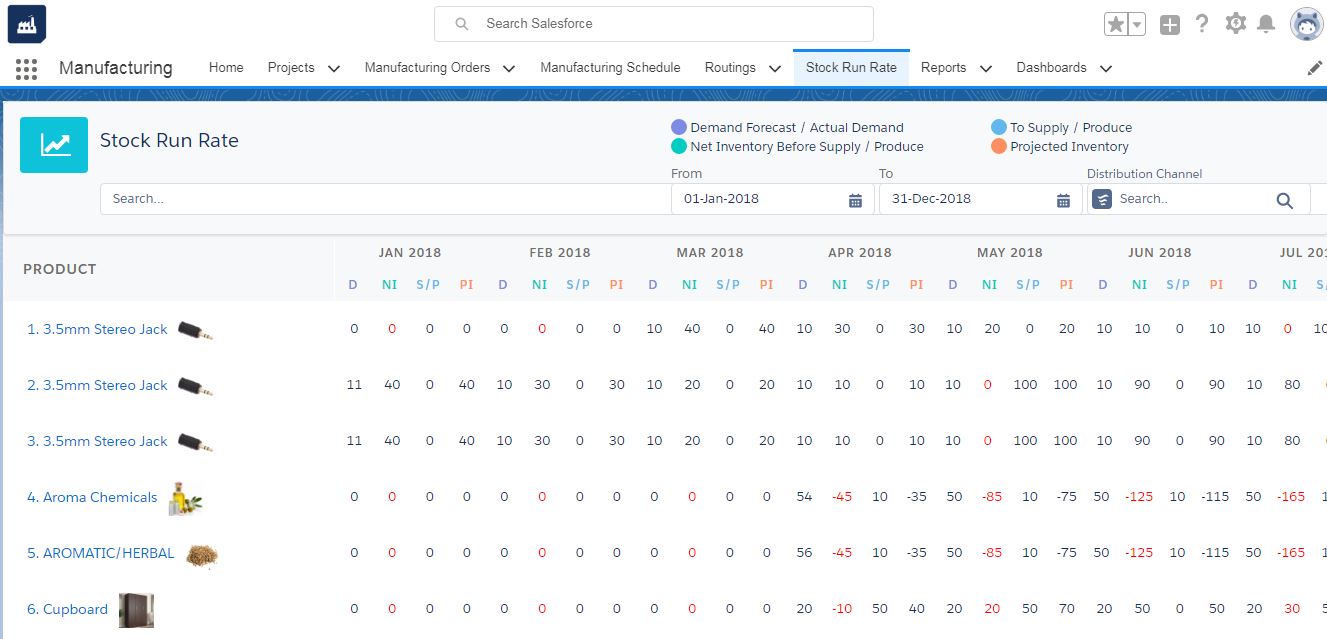

- To view the stock run rate report, navigate to the App menu > Stock Run Rate

- The From Date and To Date defaults to the current years start date and current year’s end date.

- The listed products can also be filtered based on the Distribution Channel.

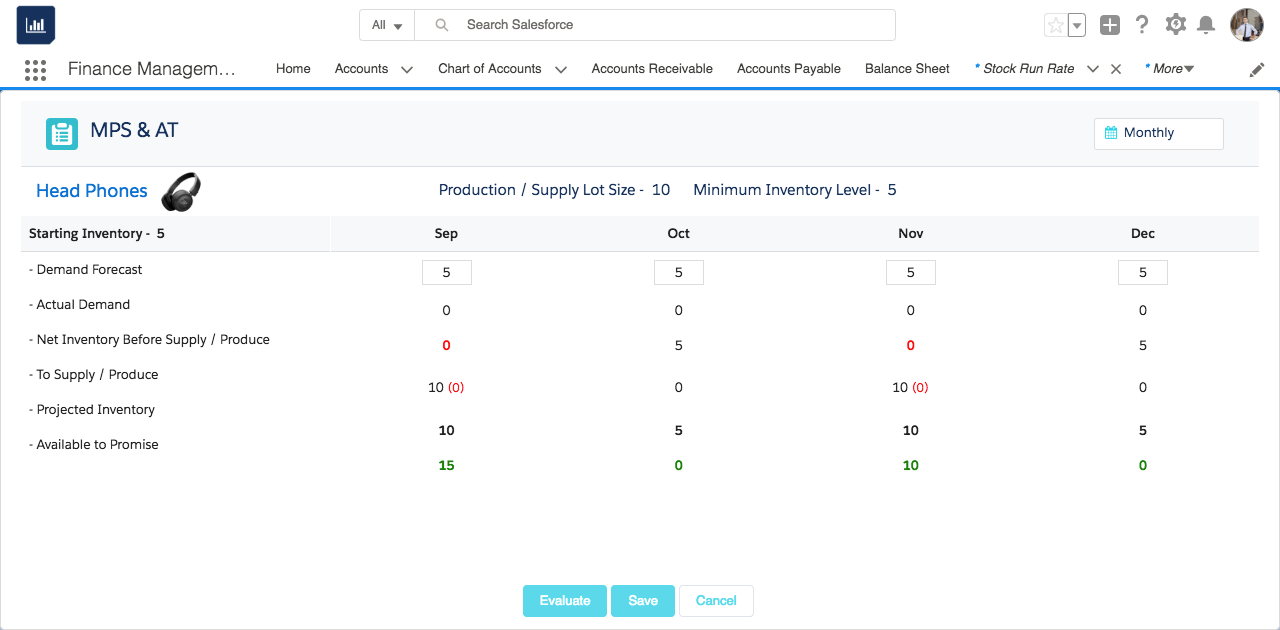

- Upon clicking Individual product, the system brings its MPS (Master Production Schedule) and ATP (Available to Promise) in a Monthly view.

- The demand forecast describes the historical data or the user-specified default demand forecast data in the MPS.

- The stock run rate report shows the Actual Demand and Net inventory calculated before the production of an item. The Net Inventory is evaluated every time the demand forecast is changed. The forecasting is based on the inventory levels specified on the MPS record.

- You can also create purchase orders and manufacturing orders by clicking the Create Purchase Orders and Create Manufacturing Orders hover buttons available at the To supply/ Produce information.

- You can view the Projected Inventory and Available to Promise quantities for each item. The calculations are time-based usually evaluated based on the scheduled period.