Manufacturing Order

Estimated reading: 3 minutes

811 views

How to create a Manufacturing Order:

- Form the App launcher go to the Manufacturing module.

- To create a Manufacturing order, go to the ‘Manufacturing Workbench’ tab

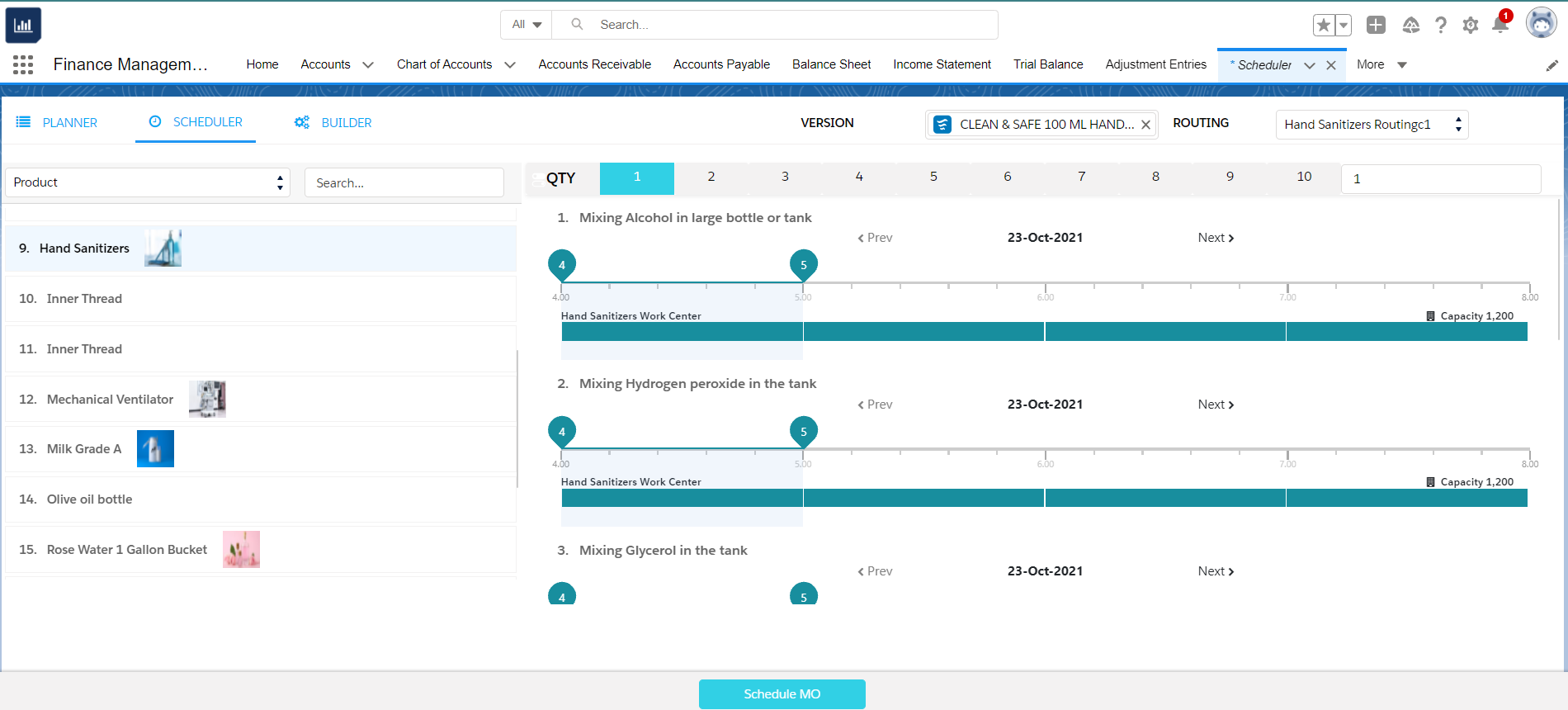

- Click on the scheduler tab to schedule a manufacturing Order.

- On the left-hand side, you will find all the products listed for manufacturing or you can search from the search bar provided.

- Click on the product that needs to be manufactured. You can see the process cycles in the scheduler to schedule these process cycles to a specific time and date.

- Enter the quantity required to Manufacture in the QTY filed provided.

- Click on the ‘Schedule MO’ button to schedule the order.

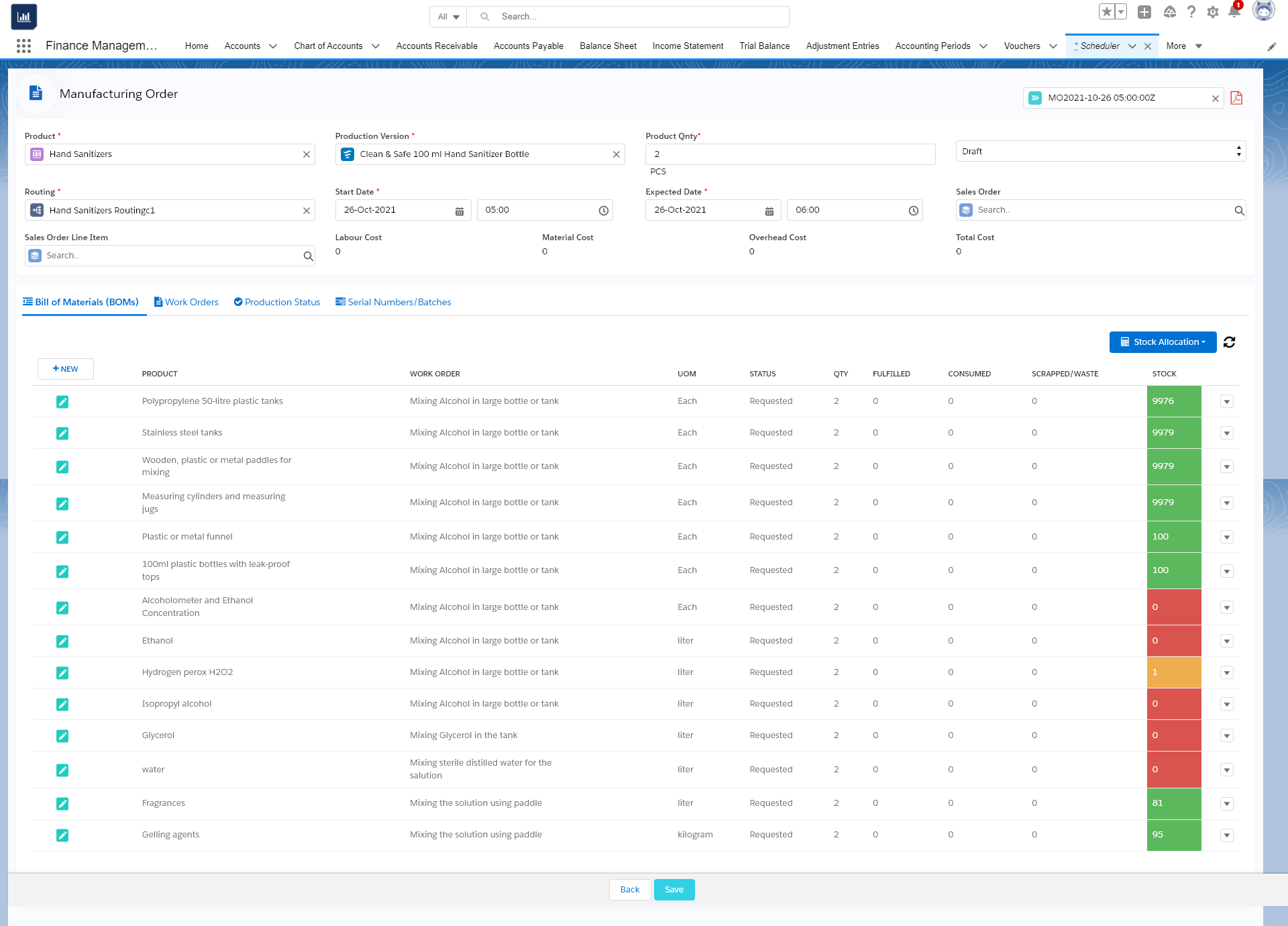

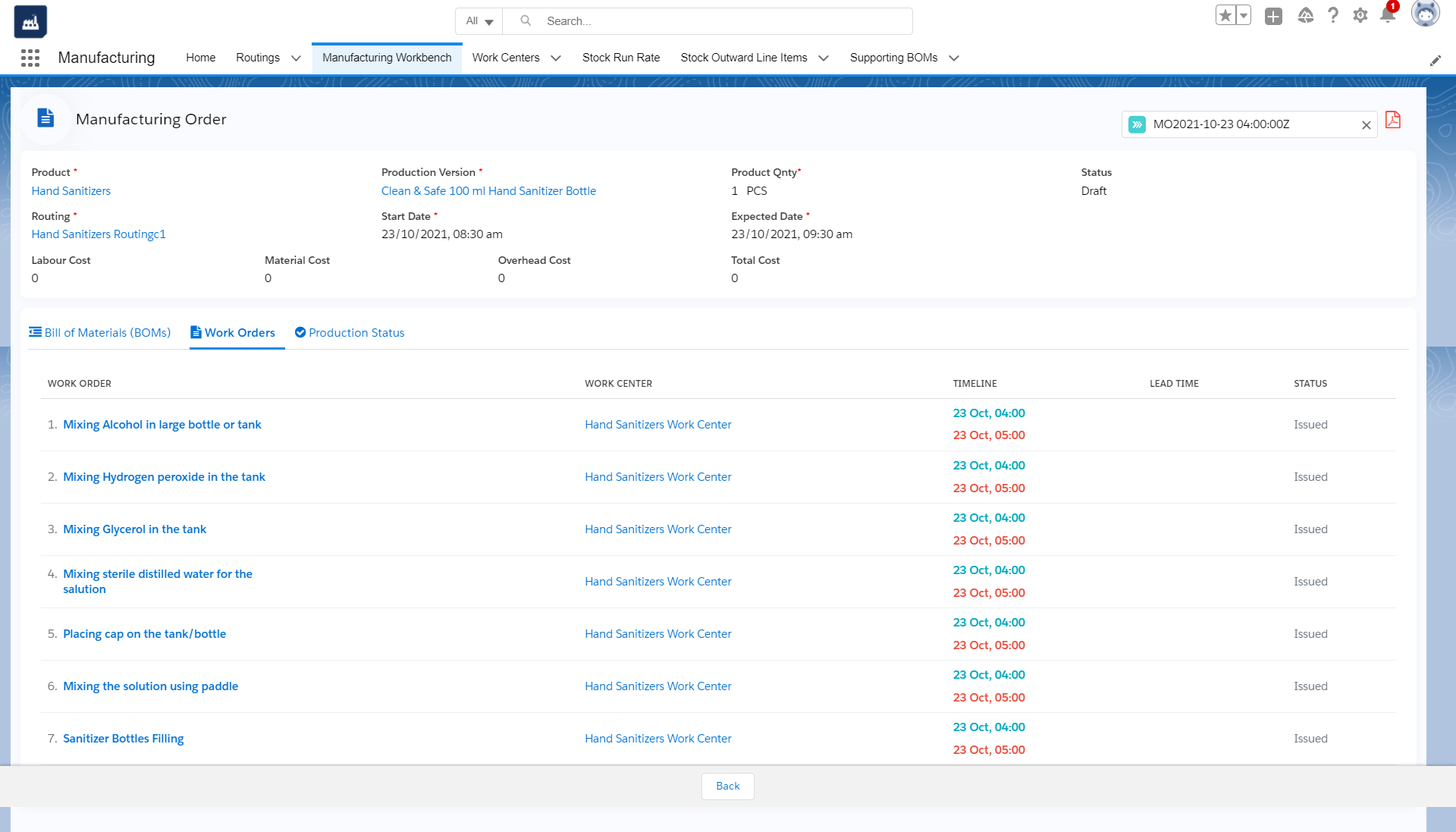

- On the next page, you can see all the details for the manufacturing order.

BOM’s tab – This shows the Bill of material required to produce the final product.

Work orders tab – Show all the work orders that need to be completed to produce the final product.

Production Status – This shows the status of the current production.

Serial Numbers / Batches – If the MO Product is Serialise product then it will generate the serial numbers or If the LOT Tracked product the system will generate Material Batches / Lots.

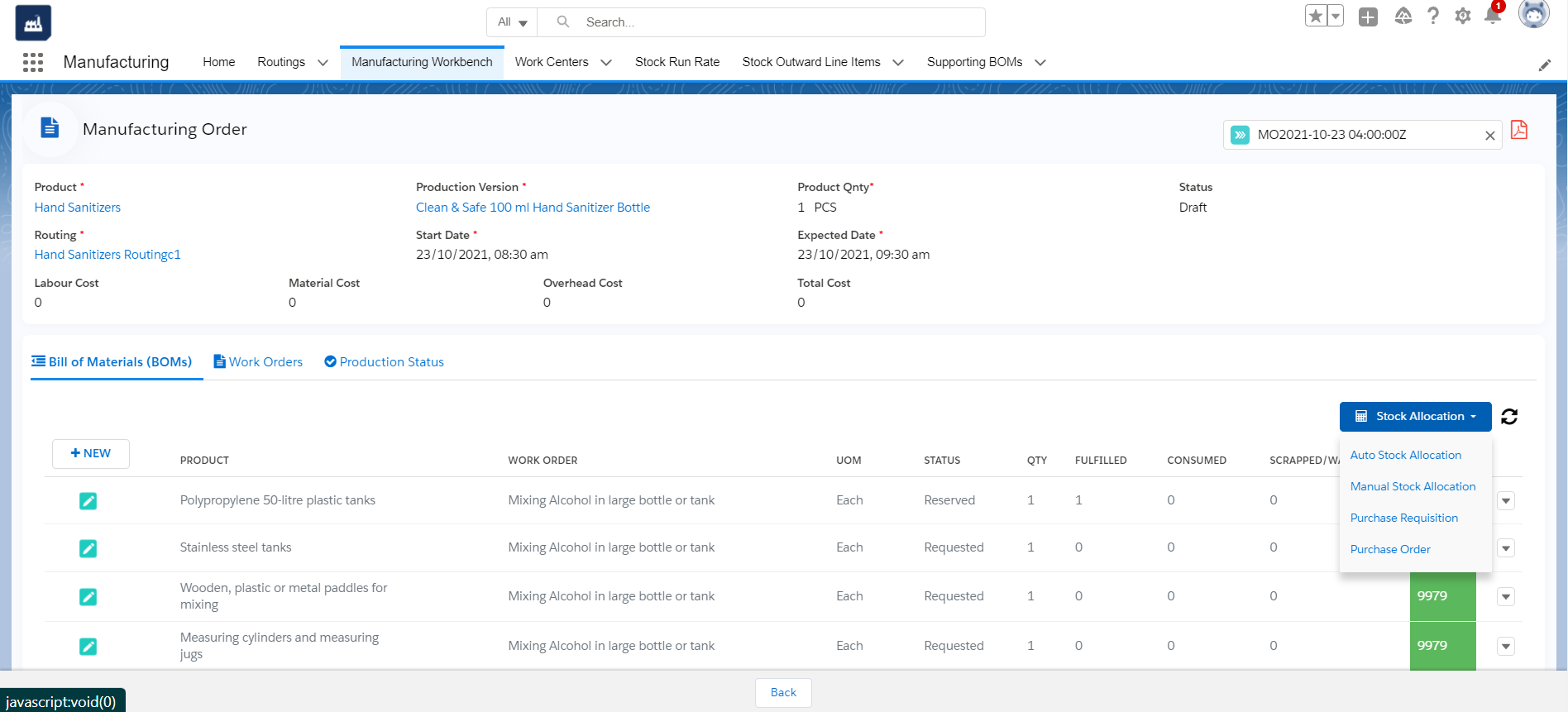

- Now Allocate the stock for all the BOM’s as required for the manufacturing of the product.

- Click on the ‘Stock Allocation’ button to allocate stock manually or select the ‘Auto stock Allocation’ button to fulfill stock automatically.

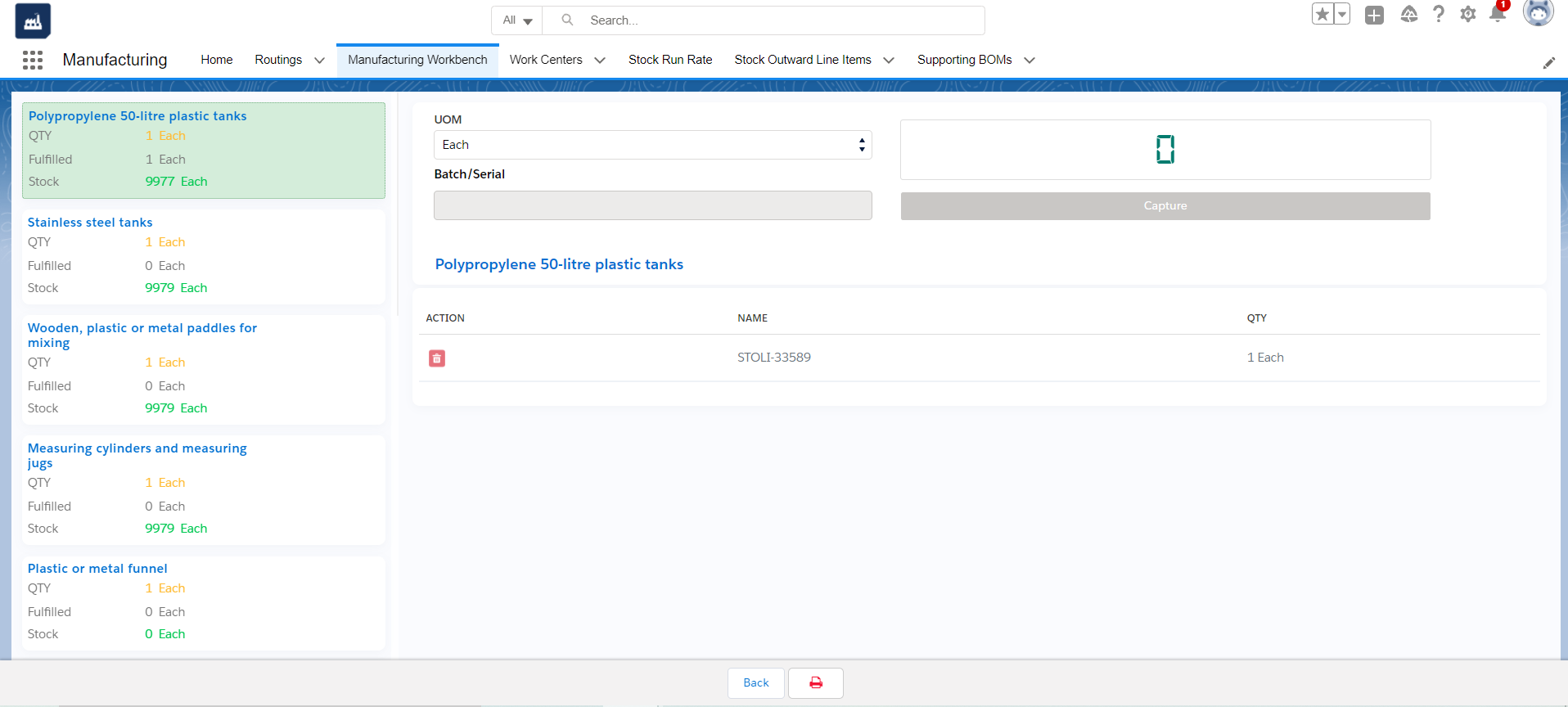

- When clicking the Stock allocation button, this page will appears to enter the stocks required for each BOM’s. Manually enter the values and click the ‘Capture’ Button to save the stock.

- Similarly allocate the required quantities for all the BOM’s.

- When all the stock is fulfilled. Click on the ‘Work order’ tab

- Complete all the work orders to complete the Manufacturing process.

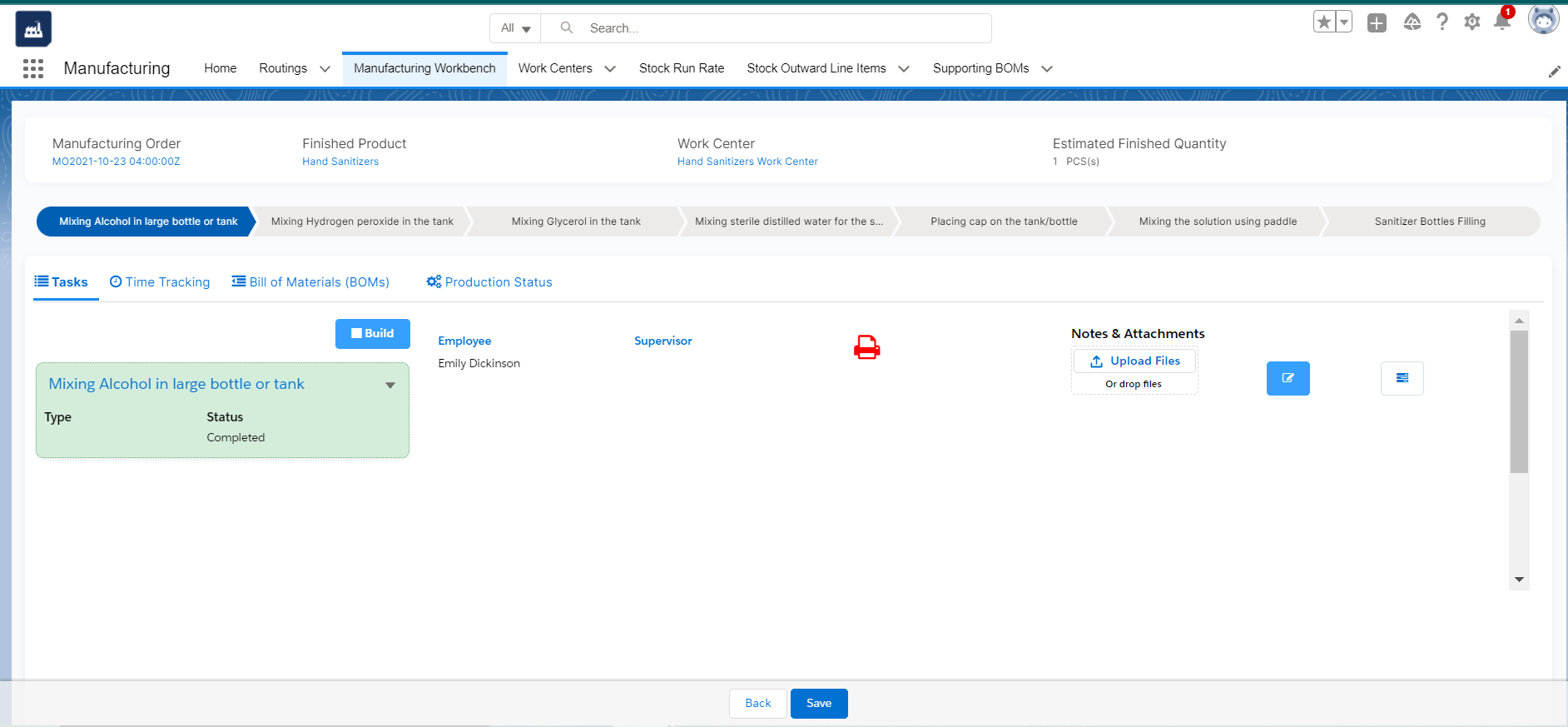

- Click on the first work order. Press the start button to start the process. Then click

on the Play button to begin the operation. Click the green ‘Complete Button’ to complete the process. When done click the ‘Build’ Button.

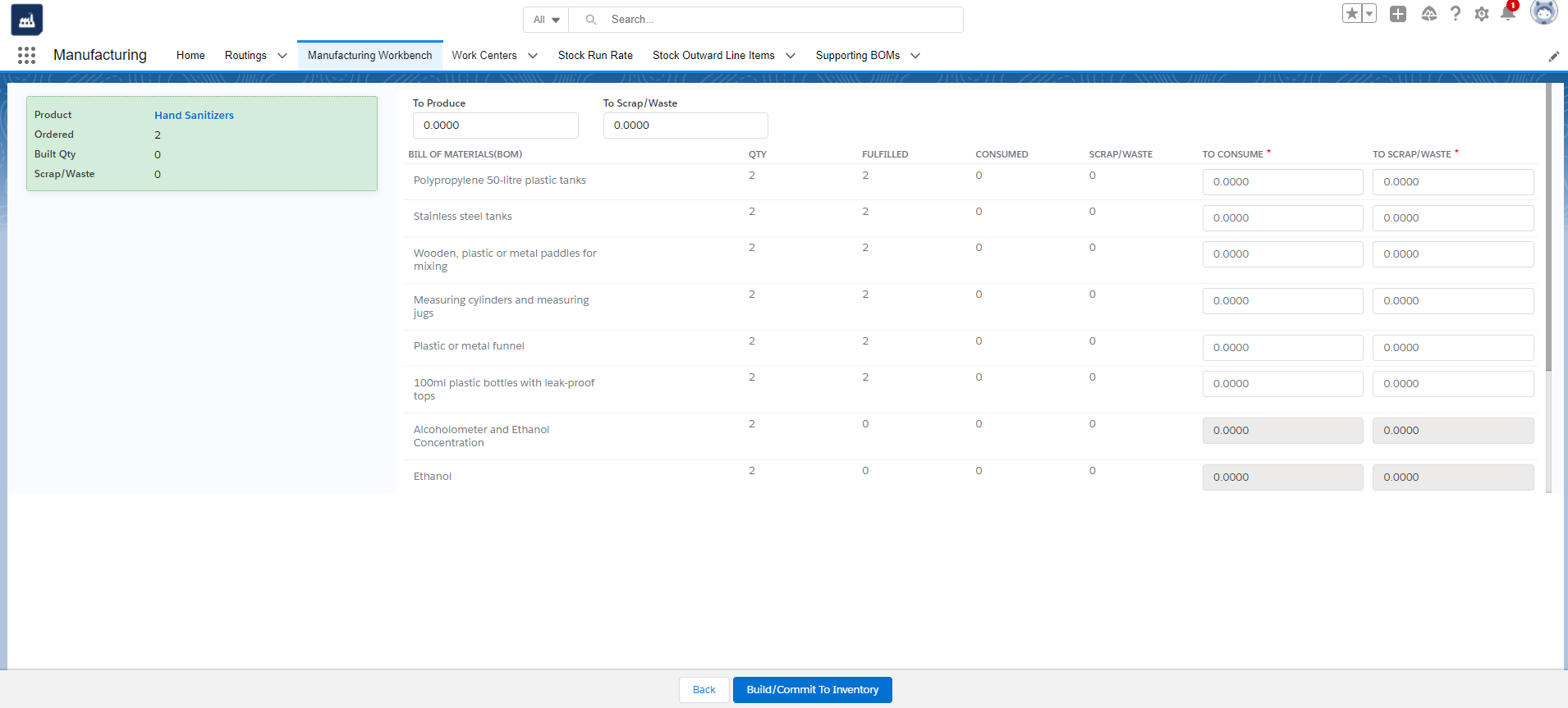

- Clicking on the Build button will navigate you to another page and enter the quantity of BOMs consumed in that Process Cycle/Work Order. Enter the vales and click the ‘Build /Commit to-Inventory’ button.

- Similarly go to the next work order and do the same for each operations. Complete all the operations specific to that Work Order. Then click the ‘Build /Commit to-Inventory’’ button.

- Clicking the ‘Build /Commit to-Inventory’’ button at the last Work Order /Process Cycle or where the WIP is set, will navigate to another page there enter the quantity that has been produced. You can also choose the type as Produced or Scrapped from the ‘type’ picklist depending on the finished product produced.

- Enter the quantity produced in the quantity field and click the ‘Build/Commit to Inventory’ button.

With this, your Manufacturing is now complete.